Share this post:

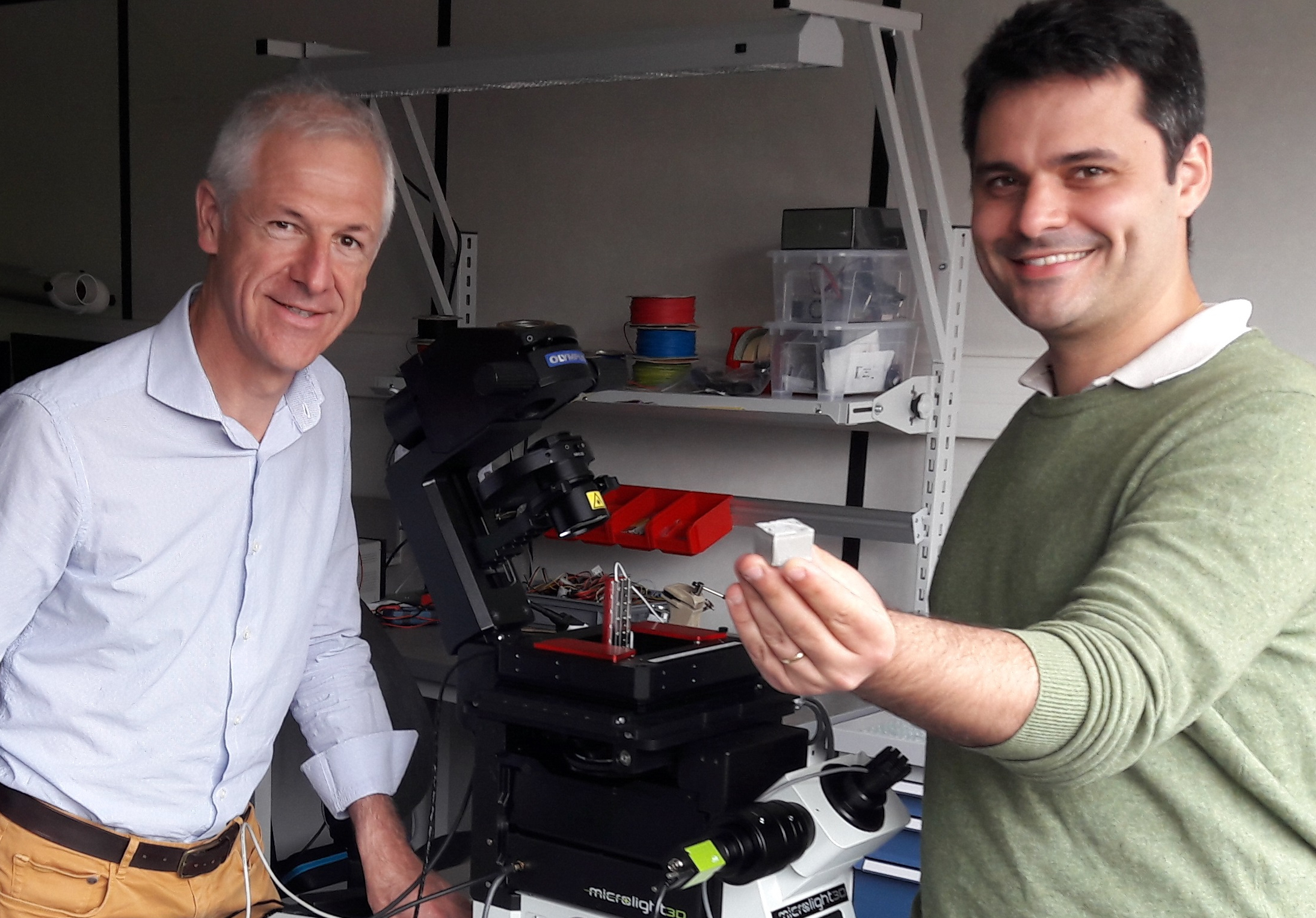

Grenoble, France, June 15, 2021 – Microlight3D, a specialty manufacturer of high-resolution micro-scale 2D & 3D printing systems for industrial and scientific applications, today announces the award of FET-Open European funding to develop microstructured concrete that will transform a buildings capacity to cool down, naturally.

This nanotechnology project, led by MIRACLE – a European consortium of five universities and Microlight3D, has the potential to revolutionize the construction industry and considerably lower the impact concrete buildings have on the environment.

“By using microstructured concrete, buildings will be able to cool down naturally and thereby reduce the ‘urban heat islands’ that build up in cities during summer heatwaves, which can make these spaces unbearable,” said Denis Barbier, co-founder & CEO of Microlight3D. “This structural building material, which can cool down by itself, will also reduce the energy consumption used for air conditioning and benefit the climate by lowering CO2 emissions.”

The consortium selected Microlight3D for the ability of its 3D microprinting technology to create 3D microstructures at ultra-high resolution, in materials rigid enough that they can be used as molds for concrete and create microtopographies.

In this project, Microlight3D will use its two-photon polymerization technology to create microstructures which will be used as molds for concrete. This will allow steel microfibers to be inserted inside the microtopography variations created at the surface. In doing so, the concrete will be transformed into a photonic metamaterial, converting the solar heat into infrared wavelengths that are then reemitted through the atmosphere. The photonic meta-concrete is thereby able to expel heat from buildings into outer space without consuming any extra energy.

“Microlight3D is proud to participate in a project aimed at creating cities that are more pleasant to live in and more respectful of the environment,” said Philippe Paliard, co-founder and head of users & applications at Microlight3D. “It is exciting to see that our two-photon polymerization technology can offer solutions to, and have a real impact on, combatting environmental issues.”

The project will run four years. Led by the Spanish Superior Council for Scientific Research (CSIC – Madrid), members of the MIRACLE consortium (Photonic Metaconcrete with Infrared RAdiative Cooling capacity for Large Energy Savings) include:

- Technische Universitat Darmstadt (Germany)

- Universidad Publica de Navarra (Pamplona, Spain)

- Fundacion Tecnalia Research & Innovation (San Sebastian, Spain)

- Katholieke Universiteit Leuven (Belgium)

- Politecnico di Torino (Italy)

- Microlight3D (Grenoble, France)

About Microlight3D

![]() Microlight3D is a manufacturer of high-resolution micro-scale 2D & 3D printing systems. The company enables scientists and industrial researchers with new design needs to produce the most demanding precision micro parts in any geometric or organic shape, with a flawless finish. By combining 2D & 3D microprinting techniques, Microlight3D offers customers more flexibility in creating larger complex parts. It aims to provide faster and more complex micro-fabrication systems for tomorrow’s applications. Microlight3D’s equipment is designed for application in micro-optics, microfluidics, micro-robotics, meta-materials, cell biology and microelectronics. Microlight3D was founded in 2016, following 15 years’ research and development of its 3D microprinting technology at Grenoble Alpes University (UGA). The company is located in Grenoble, France.

Microlight3D is a manufacturer of high-resolution micro-scale 2D & 3D printing systems. The company enables scientists and industrial researchers with new design needs to produce the most demanding precision micro parts in any geometric or organic shape, with a flawless finish. By combining 2D & 3D microprinting techniques, Microlight3D offers customers more flexibility in creating larger complex parts. It aims to provide faster and more complex micro-fabrication systems for tomorrow’s applications. Microlight3D’s equipment is designed for application in micro-optics, microfluidics, micro-robotics, meta-materials, cell biology and microelectronics. Microlight3D was founded in 2016, following 15 years’ research and development of its 3D microprinting technology at Grenoble Alpes University (UGA). The company is located in Grenoble, France.