Share this post:

Luminis merges two 3D printing functions, enabling microFAB-3D users to prepare, view, control and print micron-sized 3D objects in single step

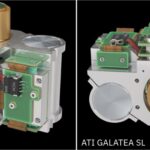

Grenoble, France, November 7, 2023 – Microlight3D, the specialty manufacturer of high-resolution micro-scale 2D & 3D printing systems for industrial and scientific applications, today announces the launch of Luminis, its proprietary Computer-Aided Manufacturing (CAM) software, making its microFAB-3D apparatus faster and easier to use for printing 3D objects 100x’s smaller than a strand of hair.

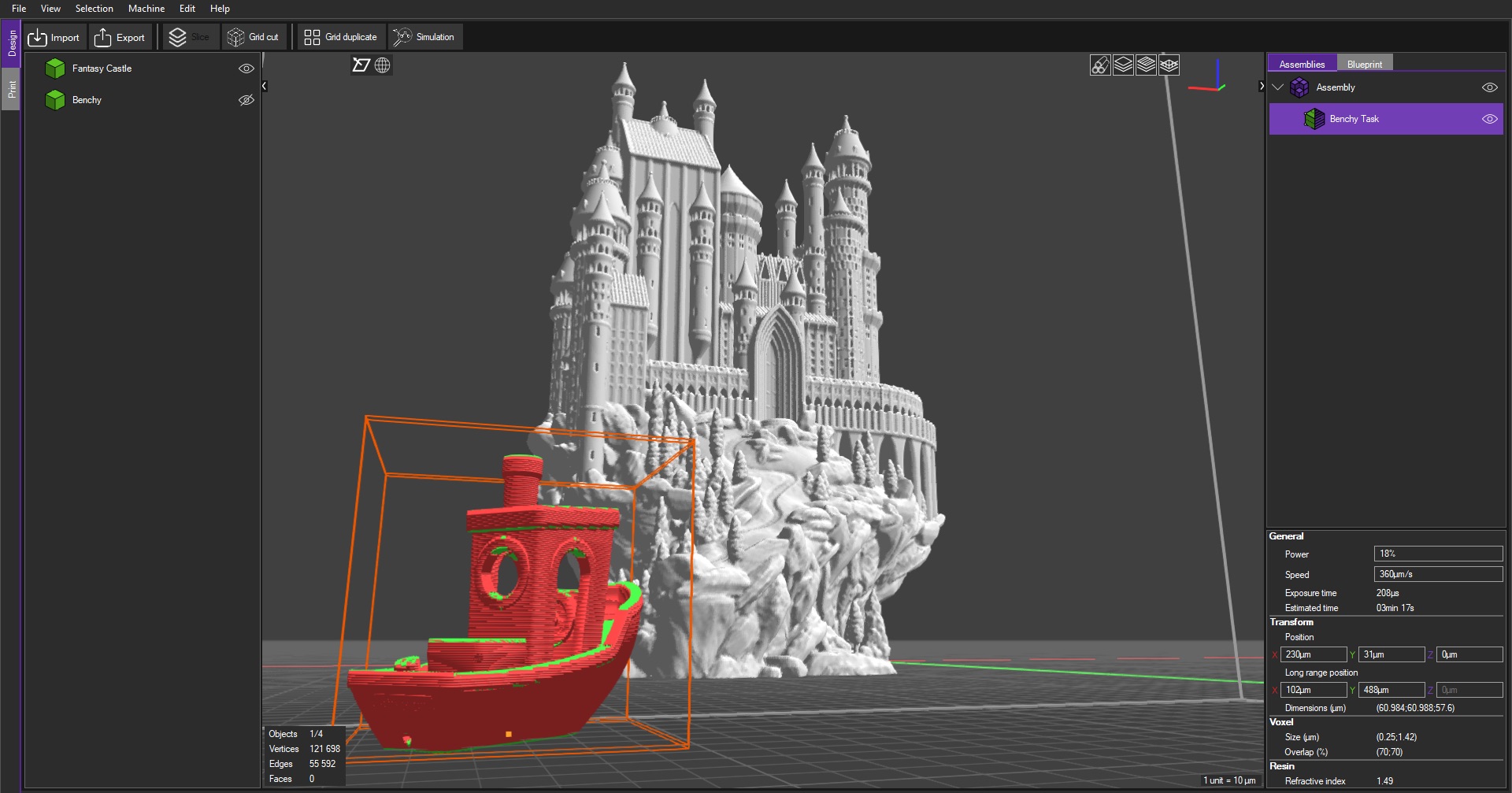

Luminis merges two key 3D microprinting functions into one single step. It replaces two pieces of software: one used to prepare an object for 3D printing and the other to control microFab-3D when printing.

The switch to Luminis means that microFab-3D users from any research laboratory or industry will have more flexibility and find it easier to prototype objects for application in micro-robotics, micro-optics, microfluidics and cell culture & tissue engineering, among a variety of micro devices or materials.

“Microlight3D developed Luminis with the emphasis on ‘user-friendly’ to allow both proficient and novice users to experience the simplicity and efficiency of 3D microprinting with microFAB-3D,” said Denis Barbier, CEO at Microlight3D. “We have succeeded in making the 3D microprinting process faster, as we no longer need to export from one software to another. This means preparing an object for manufacturing now takes half the time. Thanks to Luminis, we have made microFAB-3D more powerful and better adapted to high precision 3D printing, as the equipment recognizes with greater accuracy what the user wishes to print.”

Compared to the software approaches (Simpoly and Lithos) previously used by Microlight3D, Luminis is 50% faster in preparing an object for manufacture: down from 31 to 16 seconds. Other time-saving features include STL (stereolithography) import, which is 10x times faster, and slicing times have been divided by seven, from 63 to just nine seconds. The 3D printing process also has 35% fewer clicks, from 14 to nine.

Luminis is a software suite specifically customized for MicroFab-3D that Microlight3D is positioning as the ‘go to’ tool to facilitate high-resolution 3D microprinting for research or industrial engineers. Ultimately, the company sees users saving valuable time by having better visualization in both 3D and camera view, and more control when changing manufacturing parameters within the software.

More flexibility for users to choose what they want to do

Luminis is more powerful in conducting upstream inspection of print jobs due to the 3D view that takes physical realities (voxel size) into account. 3D visualization also gains in performance, from 40fps to 60fps under the same load.

Two key steps are required to 3D print an object at micron level: (1) the object needs to be converted into trajectories, and (2) the apparatus needs to follow coordinates. Luminis performs this critical conversion step, enabling users to have more choice in what they wish to do.

Luminis offers:

- Cutting and duplicating, according to a grid

- Simulation of a 3D print with a polished, finished look

- More accurate print-time estimation

- Automated dose tests for rapid prototyping

- Camera overlay for alignment (to print on top of already structured substrates or parts)

- A resist profile to help users develop their processes

About Microlight3D

Microlight3D is a manufacturer of high-resolution micro-scale 2D & 3D printing systems. The company enables scientists and industrial researchers with new design needs to produce the most demanding precision micro parts in any geometric or organic shape, with a flawless finish. By combining 2D & 3D microprinting techniques, Microlight3D offers customers more flexibility in creating larger complex parts. It aims to provide faster and more complex micro-fabrication systems for tomorrow’s applications. Microlight3D’s equipment is designed for application in micro-optics, microfluidics, micro-robotics, meta-materials, cell biology and microelectronics. Microlight3D was founded in 2016, following 15 years’ research and development of its 3D microprinting technology at Grenoble Alpes University (UGA). The company is located in Grenoble, France.

To download documents, you can right-click on the links above and chose « Save link as… »